Rear End:

The best production Chevy rear end for competition use in period was the 12 bolt. Light and strong, it coped well with the rigours of competition use. This is what was fitted to all Trans-Am Camaros.

It makes sense for me to fit either a Chevy 12 bolt or Chevy 10 bolt to my car. I’d spoken about this quite a lot to Ian Woodward, and he recommended a 10 bolt, which he uses on most of the Chevy and Pontiac Australian Trans-Am cars he builds. He likes the fact they’re light and really strong with the right parts installed. However, as much as I’d love to fit a Chevy 10 bolt, and it would just bolt right up, it probably isn’t the best option for me in the long term.

I’ve only ever seen one grainy photo showing the rear end of Craig Fisher’s Firebird, and this car was fitted with a Pontiac 10 bolt. This, despite the car starting life as a Camaro. Despite Chevrolet, Pontiac, Oldsmobile etc all being General Motors brands, they were still operating largely as single entities in the 1960s, using their own engines, rear ends, and other parts, even if they shared the same basic platform for their various models. So while the early Firebirds were really just Camaros with a few sheet metal changes, underneath they had different engines and rear ends.

Photo courtesy CRG forum.

Further confirmation that the Fisher car used a Pontiac rear end is that the FIA Homologation Sheet for the model in 1968 depicts a Pontiac 10 bolt. In addition, my good buddy Bruce Thompson who owns the T/G Racing factory 1969 Firebird later raced by Rod Coppins in New Zealand, confirmed this to be the case, telling me the SCCA told Terry Godsall in 1968 that he would need to fit a Pontiac rear end to his car if he wanted to race a Firebird in the Trans-Am series.

I’d love to run a Chevy 10 bolt in my car. The Historic Muscle Car rules allow it. Hell, there are even Camaros racing in HMC with Ford 9 inch rear ends. So if all I ever did was race the car in HMC, a Chevy rear end would be fine. And who knows, maybe an FIA inspector wouldn’t even notice the difference between a Chevy 10 bolt and Pontiac 10 bolt. Maybe they’d just count the number of bolts on the housing and give me the thumbs-up. Maybe they wouldn’t even bother doing that. But the FIA homologation sheet for my car shows a Pontiac 10 bolt, and I don’t want to be in the position where I get caught out and have to build an entirely new rear end because I took a punt on the Chevy unit slipping under the radar.

Bruce Thompson has been a massive help in this area. Of all the Firebirds built to contest the Trans-Am series in 1968 and 1969, his is the only one to have survived still fitted with its original rear end. In fact, its believed the only other Firebird that raced in the Trans-Am in 1968 and ’69 to have survived is the Jon Ward built car raced by Jerry Titus in the last T/A event of 1968, and which Titus and Ward drove to their impressive 3

rd outright in the 1969 Daytona 24 Hours. But this car went to Mexico in 1969, and raced there for many, many years. It evolved and evolved, and continued racing hard well into the 1980s, and was heavily chopped about. And as such, it was stripped of most of the parts it was built with. Its now back in the US, but really only the shell is original. So this car doesn’t provide the all-important clues that Bruce’s does.

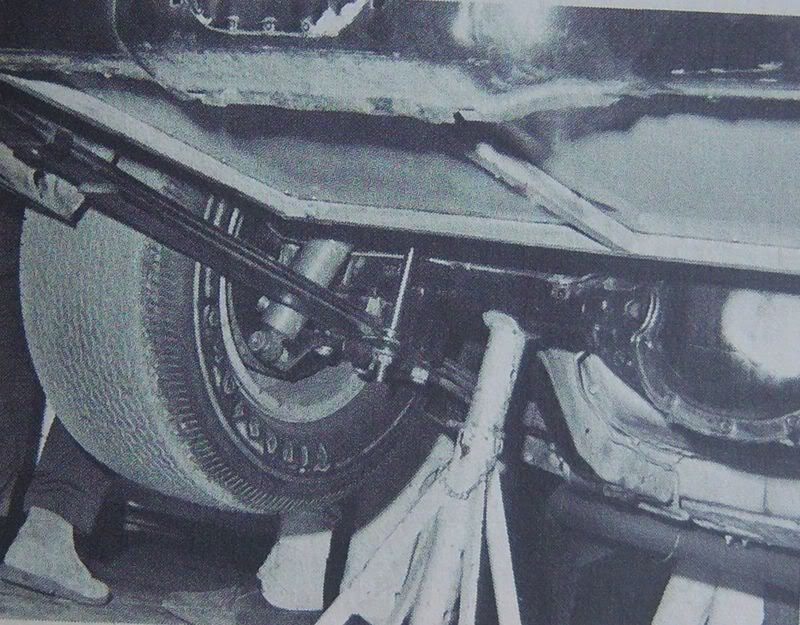

The rear end in Bruce’s Firebird is a 10 bolt Pontiac, and it’s a heavily customized piece of artwork built by T/G Racing. It features a box fitted to the cover for increased oil capacity, the centre section from a full-size Pontiac (Bonneville etc) with 12 bolt ring gear and 31 spline axles. The outer wheel bearings have an inner race so they don’t run directly on the axle shaft. There is just so much work that went into this piece. And nobody other than the T/G Racing mechanics, and the odd nosey competitor, got to see it. Luckily its survived, and Bruce has preserved it perfectly for us all to enjoy.

I hope Bruce adds some more detail on this awesome piece of kit.

As for my car, I haven’t yet researched what components are available for the Pontiac 10 bolt. Frustratingly, parts are not interchangeable between the Chevy and Pontiac items. I have plenty of time to look further into this.

Reply With Quote

Reply With Quote