I have definitely run out of superlatives to be able to comment Paul.

I have definitely run out of superlatives to be able to comment Paul.

Thanks guys!

It will be good when it can turn its wheels under its own steam.... preferably rather quickly

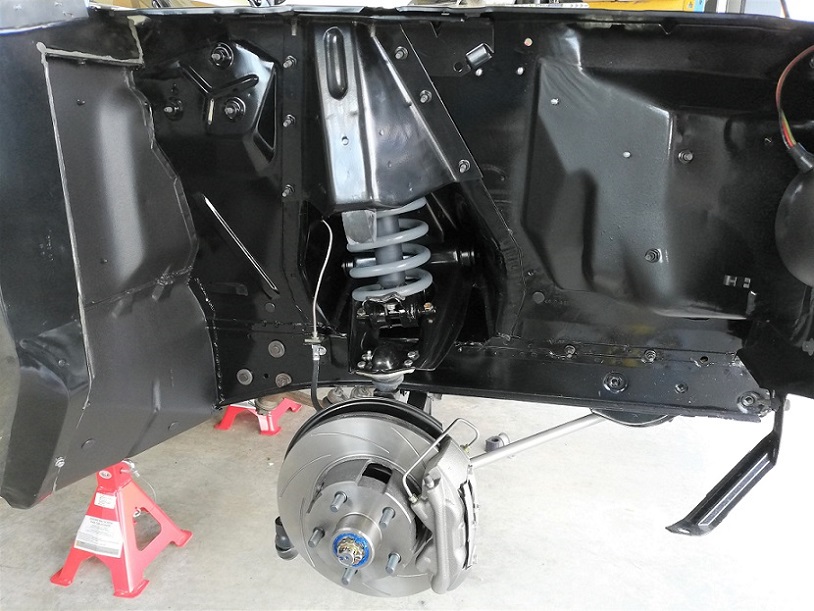

The rest of my parts arrived yesterday from USA, so I could get on with the front suspension. I fitted the upper and lower control arms, new springs, restored the torsion bar, and fitted the HD spindles.

The 1964 V8 Falcons had from factory, heavy duty tierod ends, and matching spindles, the drag link and idler arm housing was also HD (you can see it has 3 bolt idler arm housing on the chassis vs Mustang 2 bolt) . When Holman Moody built the 15 cars they replaced the OEM spindle with another heavy duty larger spindle and also used their own HD spring perch as shown.

Last edited by Paul B; 03-19-2020 at 09:19 AM.

Nice

Thanks Bruce,

I have been fitting the original type Kelsey Hayes 4 pot calipers and rotors, Right side, I needed to rework the rotor back plates to fit the HD spindles. These are the same brakes that were used on the later Mustang GT350s but the Falcon Rallye Sprints also had an in line Hydrovac booster mounted where the battery was.

This is a picture of the 1964 FIA Homologation 1250 Left Front brakes

Very interesting, I found an article on Kelsey Hayes brakes and the Chrysler Valiant entered in the 1964 Monte Carlo Rallye also had the very same brakes as the Falcon.

Last edited by Paul B; 03-07-2020 at 06:07 AM.

Not trying to be a rivet-counter, but are grooved rotors period correct??

No they are not, but they are only decent rotors found so far, most of the non grooved ones are not produced from very good quality material. Still looking, these will do for the meantime till I find something else.

Didn't know that. Wow. You don't want second rate materials in the brakes, so I can well and truly understand your decision there!!!

Rotor warping is a real pain especially under track conditions , bedding them and heat prepping helps a lot but if the metallurgy is not up to scratch it can be more rotor change outs and reskimming etc. Cheers

I made up all of the front brake lines for the master cylinder to booster, booster to junction and to front wheels, then fitted them up. I also finished fitting the brakes and torqued everything down. A lot of brake lines with a remote in line booster but that's how they were made.

And spaghetti junction,

Fitted the anti sway bar and some other parts and torqued the front brake and suspension components down, re checked the camber and caster. That completes the front suspension and brakes assembly.

On to the steering now to finish that off.

Last edited by Paul B; 03-12-2020 at 08:43 AM.

Beautiful work!!

Thanks Andrew, Getting there... slowly

I fitted some interior and the front screen with the wipers too, and they work!

Also had to buff & polish the 55 year old Stainless trim, started with this

Here is the finished job

Screen & Wipers fitted also

Last edited by Paul B; 05-03-2020 at 08:22 AM.

A few more jobs done

Fitted the front upper outer shock tower supports I fabricated earlier

Also gave the Borg Warner T10 a birthday, this is the first of the Super T10s with 28 spline output.

It is always interesting seeing the different ways people have reassembled parts over the years in places they should not be.

Also this is a picture of all the RTV I found in places it should not be.

Last edited by Paul B; 06-10-2020 at 08:33 PM.

I have completed the body and trim assembly and the interior also. The wiring is all done and the alternator conversion with diode install is all completed. ready for engine, gearbox and driveline now.

So this is the road going version to get it road registered and then it will come back for the roll cage etc, it will be running complete interior as the cars did in 1964.

Last edited by Paul B; 06-12-2020 at 09:44 AM.

Paul,

Your workmanship and attention to detail is absolutely outstanding.

Even the garage floor is spotless. Well done mate.

Although your dear wife must get a lot of credit as she waited patiently for you as you spent time with your second love !

Hey, perhaps one day we can link up and spend some time together..

(Alamy photo )

Cheers,

Ken H

Last edited by khyndart in CA; 06-15-2020 at 05:29 AM.

The car looks amazing Paul. I doubt they ever looked that good at any stage of their journey from the US to Monte Carlo. The panel fit is just exceptional. The second stage (post licensing) will be just as intriguing for all of us who have followed the build. Great work!

So this is the road going version to get it road registered and then it will come back for the roll cage etc, it will be running complete interior as the cars did in 1964.[/QUOTE]

Thanks very much Ken, Nice to see it at this stage now... finally! hope you are all well there.

Cheers

Thanks Bill, I guess I am trying to emulate what this car would have looked like when it was brand new after leaving Holman Moody. The panel fit is good but not show car level, and the fiberglass has continued to shift a little, so there are a few wallows here and there, only visible when you look for it and get up close and on certain angles. I think, all things considered, it is a very close representation of what they had in the day. Well about as close as I am going to getI am finishing the engine now, street version, the race engine is coming later. Cheers

I called in today on the way back from Kapiti to see Paul and the car.

The photos are one thing but seeing the car in the flesh is just so different.

Nothing said can do justice to the amazing job Paul has done on his build.

This truely is a world class restoration and the attention to detail is unbelievable.

Paul you deserve the accolades that your extreme effort on your build of this fabulous car.

Well done my friend and I cannot wait to see is debute on the grid in HSC.

Cheers

Bruce